Groupe ATP-CGPharm is the ideal partner for the life sciences industry !

In this post, we will discuss our expertise in : Cleaning Validation.

The validation of cleaning processes in the manufacture of active pharmaceutical ingredients (API) and medicinal products is required by law (EU-GMP, PIC/S, FDA). Annex 15 of EU-GMP Guidleline defines cleaning validation as “The documented evidence that an approved cleaning procedure reproducibly removes the previous product or cleaning agents used in the equipment below the scientifically set maximum allowable carryover level.”

ATP-CGPharm is specialized in validation of cleaning processes in the manufacture of medicinal products for over 25 years. We elaborate concepts for chemically synthesized active ingredients, biologically produced active ingredients as well as for live biotherapeutic products. We are familiar with the latest trends and regulations and know the expectations of the authorities.

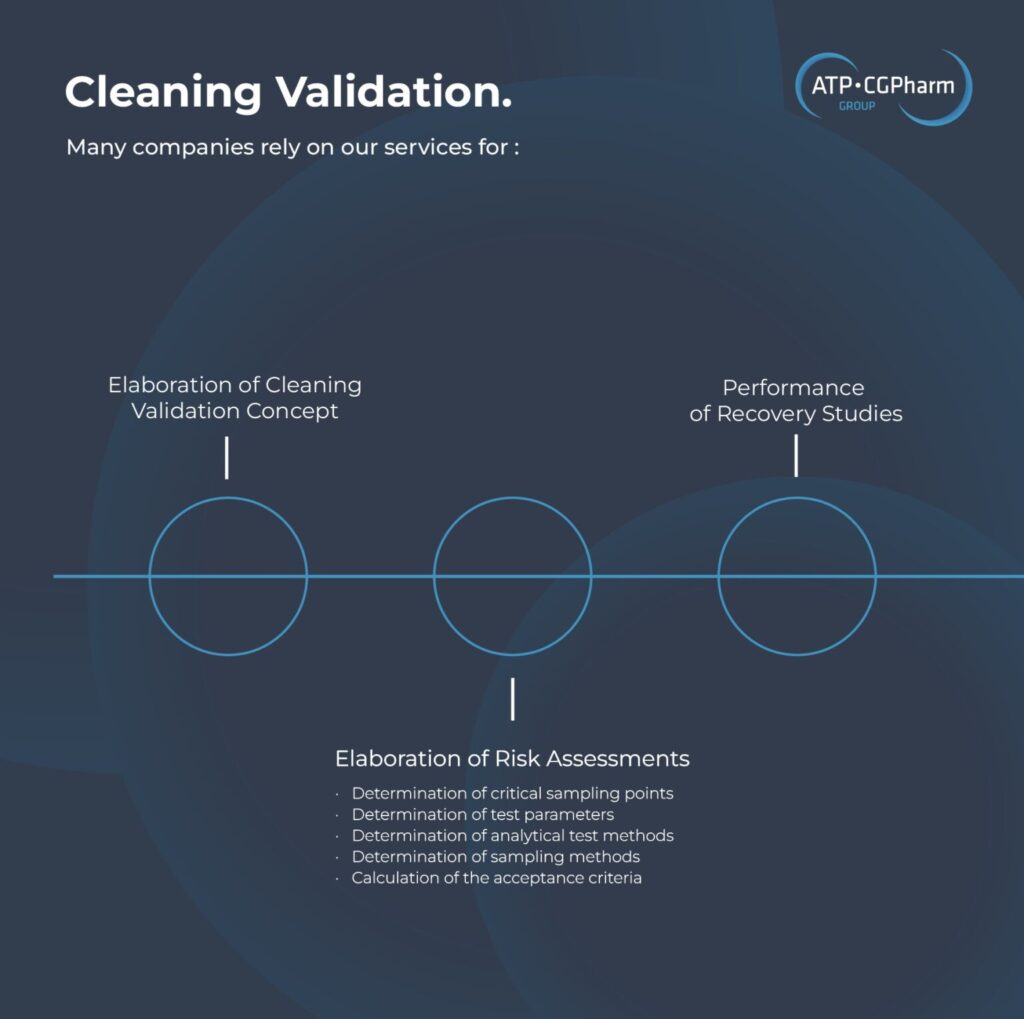

From advice to the complete planning and realization of a cleaning validation studies consisting of :

– Development of a customized validation strategy including worst case considerations and bracketing concepts

– Preparation of risk assessments

– Determination of acceptance criteria for product residues using the PDE concept (or alternatively 10 ppm criteria if no data is available)

– Determination of acceptance criteria for microbiological contamination and cleaning agent residues

– Definition of the sampling points and definition of sampling methods (swab, rinse, visual inspection)

– Execution of studies to determine recovery rates per sampling method and surface

– Determination of the analytical test methods

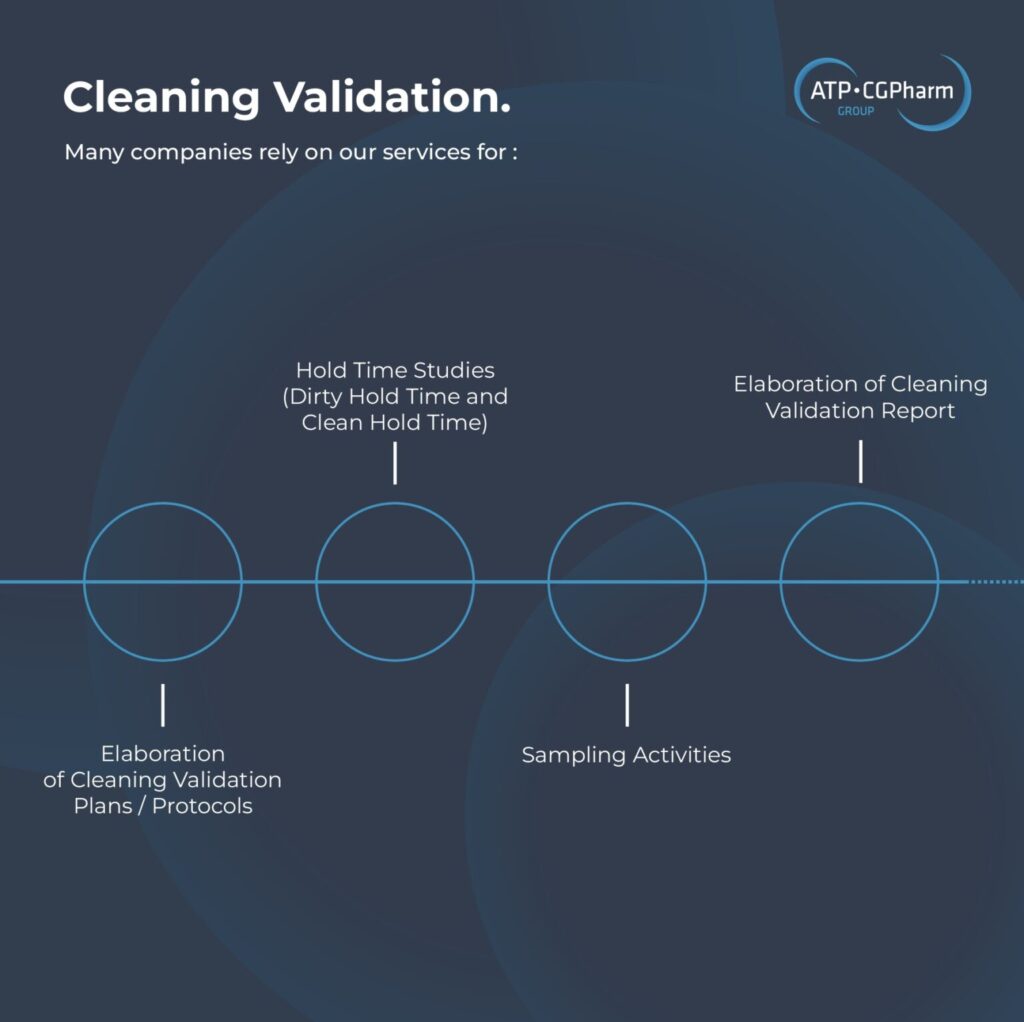

– Preparation of validation plans and protocols

– Hold time studies (Dirty Hold Time and Clean Hold Time)

– Carrying out the sampling by our qualified samplers

– Analyzing the samples, including documentation and interpretation of the results

– Initial development and optimization of cleaning procedures

– Preparation of the final cleaning validation report, summarizing performed activities, deviations, and a final conclusion

– Preparation of procedures to monitor the effectiveness of the cleaning process over time

We have extensive experience in the pharmaceutical industry and can customise our advice to your specific needs. Trust ATP-CGPharm Group for your cleaning validation projects