B

B Facility and Process Engineering

For more than 20 years, the ATP-CGPharm Group has been offering tailor-made solutions for the creation of new facilities as well as for the renovation or extension of existing installations.

Our company is known for carrying out projects that comply with the specifications, deadlines and budgets set.

The ATP-CGPharm Group is able to manage a project from the identification of needs to its realization.

Our highly experienced engineers and pharmacists support you from consulting to turnkey solutions including

commissioning and qualification for the successful implementation of your GxP compliant projects.

B

B ATP-CGPharm Group plans and realizes your GxP-compliant facilities and processes in the following areas:

> Pilot Plants and Production Facilities

– Biotech and API

– Non-Sterile Dosage Forms

– Sterile Dosage Forms

– Medical Devices

> Quality Control Laboratories

– Analytic labs

– Microbiology labs

> Research and Development Laboratories

> Warehousing

B We design and coordinate the professional and GMP-compliant implementation of:

> Cleanroom structures

> Air conditioning and ventilation (HVAC)

> Electric installations

> Sanitary installations

> Utilities

> Building automation

> Monitoring systems

> Process specific installations

> Process automation

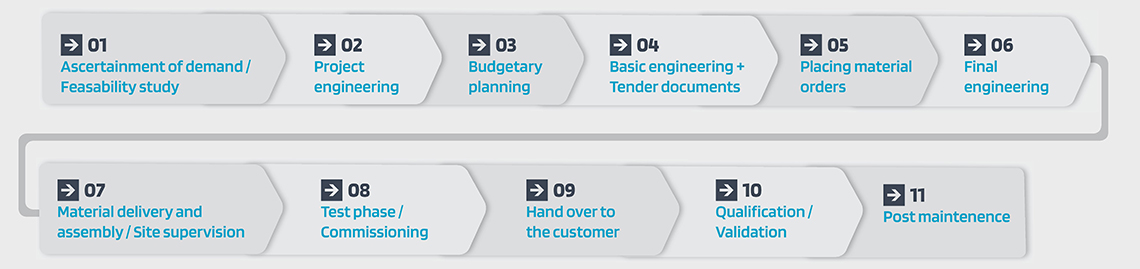

B Our typical project management in 11 steps:

01

Ascertainment of demand /

Feasability study

02

Project engineering

03

Budgetary planning

04

Basic engineering +

Tender documents

05

Placing material orders

06

Final engineering

07

Material delivery and

assembly / site supervision

08

Test phase / commissioning

09

Hand over to the customer

10

Qualification / Validation

11

Post maintenence

B If you design your facilities or processes with internal resources, ATP-CGPharm Group can also support your team

through its consulting activities or by Furnishing of Qualified Staff (Staff Leasing).